In early 2018, the global auto industry watched Tesla with a mix of fascination, skepticism, and barely concealed anticipation. Wall Street analysts were firing off dire predictions. Traditional car manufacturers—Mercedes-Benz, BMW, Audi—believed the Silicon Valley upstart had finally stretched itself too thin. Financial commentators used words like “meltdown,” “production hell,” and “impossible at scale.” Many predicted bankruptcy by the end of the year.

At the center of it all was the Model 3—Tesla’s attempt to build an affordable, mass-market electric car. Demand was enormous. Hundreds of thousands of reservations poured in. But producing that many vehicles at scale, critics insisted, would expose Tesla as a tech company trying—and failing—to become an automaker.

By spring 2018, even optimistic observers began to waver. Production bottlenecks. Missed deadlines. Cost overruns. And then came the boldest predictions: that Tesla would not survive the summer.

Analysts from established automakers whispered publicly what executives privately believed: that Tesla simply lacked the manufacturing DNA needed to mass-produce cars. Public comments from German luxury brands dismissed Tesla’s ambitions. An internal Mercedes analysis reportedly concluded Tesla would “run out of cash by summer,” while a senior BMW executive was quoted as saying Tesla “will never mass-produce the Model 3.” The Wall Street Journal described Tesla’s factory situation as “a production nightmare.”

For a moment, it seemed the predictions might come true.

And then Elon Musk did something no one expected.

THE CEO WHO SHOWED UP WITH A PILLOW

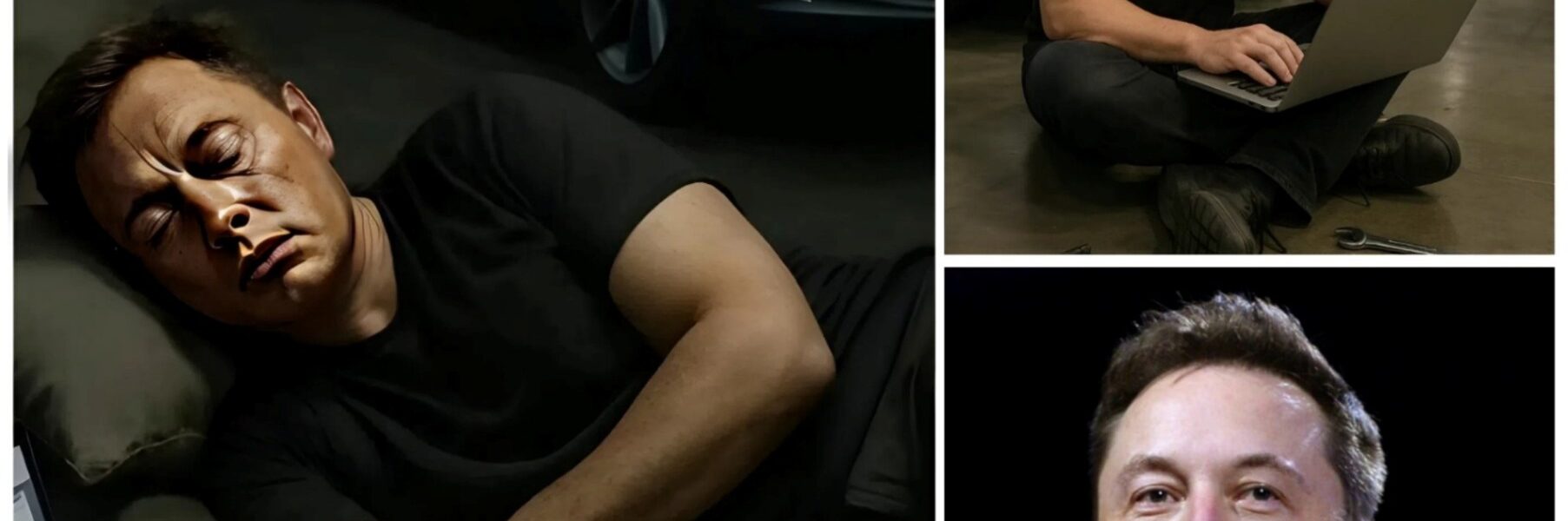

Around that time, reports emerged that Elon Musk had effectively moved into Tesla’s Fremont factory—literally sleeping beside the assembly line. Employees arriving for night shifts recalled seeing the CEO lying on a makeshift mattress, using a jacket or a pillow, running on barely two or three hours of sleep.

This wasn’t an act of symbolism; it was triage. Musk personally inspected robots, walked the floor at 3 A.M., and called suppliers in the middle of the night demanding faster parts deliveries. “We were going to die,” he later admitted bluntly. “I couldn’t ask the team to go through what I wasn’t willing to live through myself.”

In an industry where CEOs usually operate from top-floor glass offices, the image of Musk sleeping in a factory—on cold concrete floors or in a conference room—spread across global media. Some critics mocked him. Others called him irrational or unhinged. But inside Tesla, the message was clear: the company was not going to fail quietly.

A RADICAL SHAKE-UP

One of the most shocking decisions involved restructuring Tesla’s entire production line. Musk fired or reassigned layers of middle management and demanded direct daily updates from engineering and logistics teams. Tesla also built an additional assembly line under a giant tent outside the factory—a move the auto industry openly ridiculed.

But Tesla argued the tent was not improvisation. It was speed. It was engineering triage. It was survival.

Against all odds, the outdoor line helped break the bottleneck.

Musk appeared visibly exhausted in interviews—eyes red, voice strained, at times close to tears. But he also appeared determined. “Production hell,” as he famously called it, became his personal battlefield.

THE TURNING POINT

By mid-2018, something remarkable happened: the numbers began to change.

Tesla hit its target of producing 5,000 Model 3 vehicles per week—a figure critics had insisted was impossible. Analysts who once predicted bankruptcy quietly revised their reports. New buyers flooded Tesla stores. Markets reacted. For the first time, legacy automakers realized Tesla might not just survive—it might win.

Former skeptics conceded publicly that Tesla had done the unthinkable. “They pulled off something that would have broken any other automaker,” one industry veteran admitted later.

THE AFTERSHOCK ACROSS THE AUTO INDUSTRY

What happened next sent shockwaves through every major automaker headquarters from Munich to Detroit to Tokyo.

Tesla not only avoided collapse—it became the world’s most valuable car company within two years. The Model 3 became one of the best-selling electric vehicles globally. Traditional manufacturers scrambled to accelerate their EV programs. Some canceled internal combustion plans entirely. Multi-billion-dollar electrification investments were launched across the industry.

Executives who once treated Tesla like an eccentric experiment now studied it as a case study in disruption. Suppliers shifted their priorities. Governments adopted EV policies at unprecedented speed. And the auto world realized that the Silicon Valley outsider was no longer a novelty—it was setting the pace.

THE LEGACY OF 2018

The story has since become part of Tesla’s mythology: a CEO sleeping in a factory, making phone calls at dawn, inspecting broken robots, tightening bolts with his own hands, and refusing to concede defeat when every major expert predicted collapse.

To critics, it was reckless. To supporters, it was visionary. To the industry, it was a turning point.

Today, Tesla’s survival in 2018 is often cited as one of the most dramatic corporate turnarounds of the 21st century—a moment when leadership, obsession, and refusal to quit rewritten the trajectory of the global auto market.

:max_bytes(150000):strip_icc():focal(764x339:766x341)/elon-musk-2-a4fbdaf0d4bb4fb8bca7c10d13abcff7.jpg)

The companies that once predicted Tesla’s bankruptcy are now racing to catch up. And the man who slept on a factory floor to keep Tesla alive now oversees one of the most influential carmakers on the planet.

In hindsight, 2018 wasn’t the year Tesla died.

It was the year Tesla was reborn.